Rotary Draw Bender: Tube and Pipe bending basics explained

To get started bending tube or pipe with Memoli rotary draw bender, we have put together these basic metal fabrication terms to make beginning your first bending experience as easy as possible.

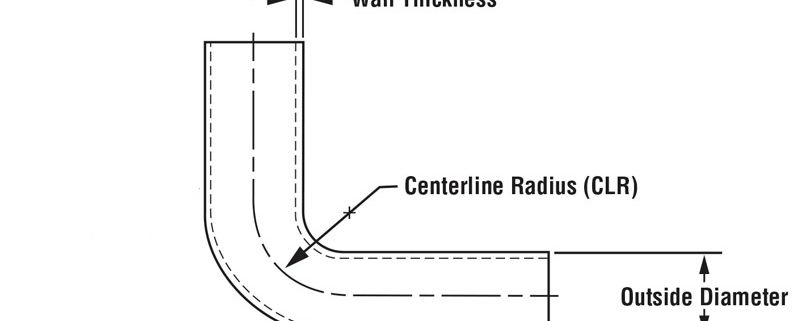

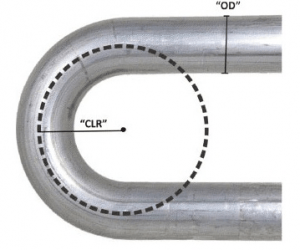

Rotary Draw Bending, Center-line Radius (CLR):

When referring to the radius of a die, we are referring to the center-line radius (CLR) that results from bending. CLR is the distance from the center of curvature to the centerline (axis) of the pipe.

When choosing a die, factors that will affect the CLR you choose include the material type and grade to be bent, wall thickness, the OD, the application or design of the end product, and overall appearance required.

Outside Diameter (OD):

The outside diameter (OD) is the distance across the extreme outside dimensions of a tube or pipe.

Inside Diameter (ID):

The inside diameter (ID) is the longest distance across the inside dimensions of a tube or pipe.

Wall Thickness:

Wall thickness is the distance between the outside diameter and the inside diameter of the pipe measured in thousandths of an inch. For pipe: Schedule determines wall thickness. It’s important to use accurate calipers when measuring this value.

The relationship between outside diameter and wall thickness has an important bearing on selecting a die.

Bend Angle (DOB):

This relates strictly to the number of degrees required in a particular bend.

Springback:

The cause of springback is uneven stretching of material during a bend. The centerline material is trying to return to its original shape, yet is constrained by the unyielding material on either side. The effect is noticed when the material is taken out of the bender.

Springback must be compensated for by adding the springback factor in to the Memoli software to the desired degree of bend. You can easily figure out the springback factor by performing test bends. Springback is not a constant factor for all materials and can even change within materials of the same OD and wall thickness. It’s extremely important to perform test bends on each batch of material you buy.

Example to set Springback with Memoli rotary draw bender:

If you want to bend a piece of tubing to 90 degrees and you determined in your test bends that the material will spring back 5 degrees, you must put in the Memoli’s software bend springback 5 degrees, and achieve your desired 90-degree bend when you remove the tubing from the bender.