ETM-H 80 tube bending machine: sectional garage door J profiles

The ETM-H 80 tube bending machine is the most effective and efficient solution for simultaneously bending two pieces at a time, J profiles for overhead garage doors without any limitation on the length of the machined profile.

In ETM-H series tube bending machines, the bending function is performed automatically.

Simplicity, robustness and precision are the key features of this particularly cost-effective line of tube bending machines.

These tube bending machines are particularly used for medium batch production, prototyping, adaptation and maintenance work.

In tube processing with multiple bends, the positioner will greatly facilitate your work; in fact, this device through its system of stops allows the exact fixing of the tube length and rotation position between bends, ensuring an excellent degree of repeatability.

FEATURES

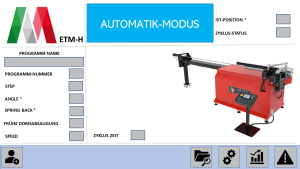

- Electronic control “Digital Bend Programming Touch Screen 2”

- Remote connection, in line with “Industry 4.0”

- Separate control pulpit

- Variable rotation speed

- Adjustable clamp pressure

- Programmable early core extraction for optimized bend quality

- Springback programming

- Movable counter-matrix slide with automatic springback

- Interchangeable shaft for small bending radii

- Positioning device for tube length and rotation, incl. 3-jaw chuck

- Positioning device for tube length and rotation, incl. hydraulic chuck (optional)

- Useful tube length 1500 / 3000 / 6000 / 8000

- Compact machine

- Mandrel lubrication system (optional)

ETM-H TUBE BENDING SOFTWARE

All ETM-H series tube benders are equipped with the “Digital Bend Programming Touch Screen 2,” an extremely easy-to-use control software via the Touch screen.

Using the latest technology, a range of essential functions can be accessed:

- Storage of 100 programs, each of them with a 10-stop sequences in the bending operation

- Adjustable bending speed

- Early mandrel extraction programming

- Springback programming

- Bend counter

- Remote connection “Industry 4.0”